PET Flake / seem dehumidifier crystallizer

Daim ntawv thov qauv

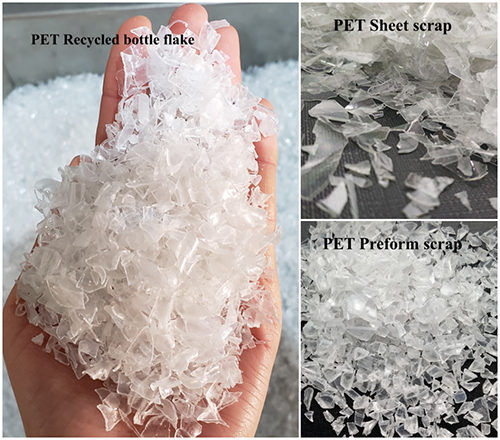

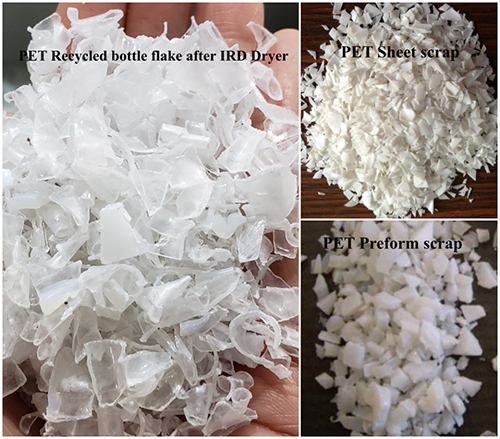

| Raw Khoom | PET Recycled flake / PET daim ntawv seem / PET Preform seem |

|

| Siv Tshuab | LHW-600 * 1000 |  |

| Qhuav & Crystallized Temperature teeb | 180-200 ℃ tuaj yeem kho tau los ntawm cov khoom ntawm raw khoom | |

| Crystallized lub sij hawm teem | 20 feeb | |

| Cov khoom siv kawg | Crystallized thiab qhuav PET scraps thiabCov dej noo kawg tuaj yeem yog li 30ppm |  |

Yuav Ua Li Cas

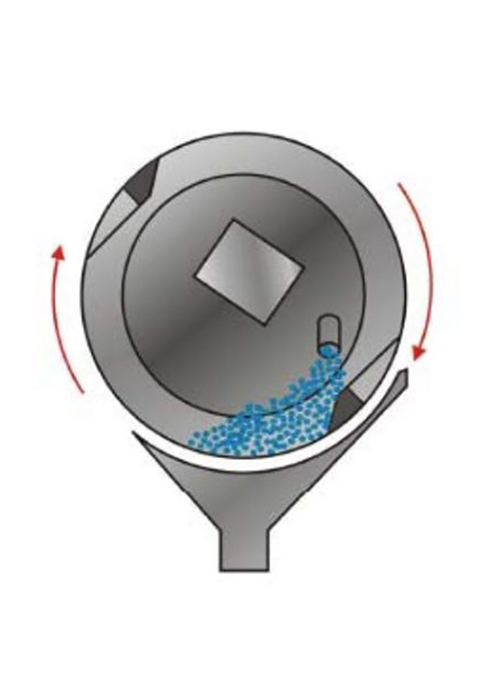

Pub/Loading

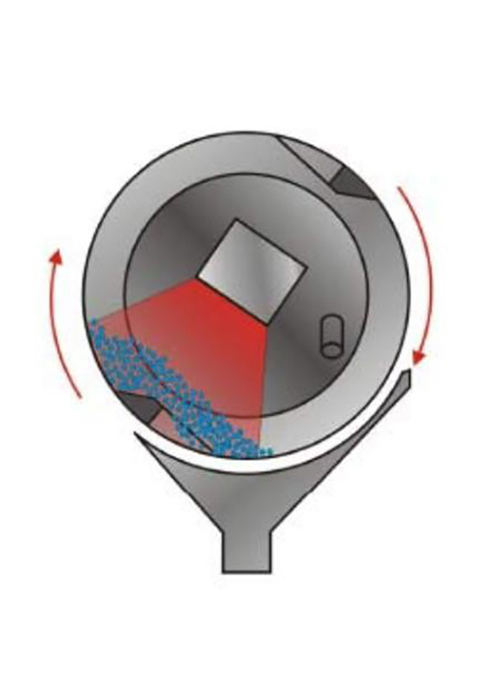

Qhuav & Crystallization ua

Tshem tawm

>> Thawj kauj ruam, lub hom phiaj nkaus xwb yog kom sov cov khoom mus rau qhov kub thiab txias.

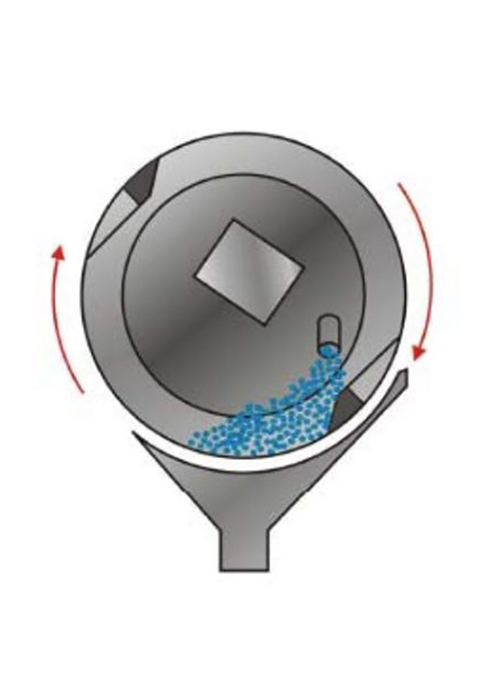

Txais yuav qeeb qeeb ntawm lub nruas rotating, Infrared teeb lub zog ntawm lub tshuab ziab khaub ncaws yuav nyob rau theem siab dua, tom qab ntawd cov PET pellets yuav muaj cua kub ceev kom txog thaum qhov kub nce mus rau qhov kub thiab txias.

>> Qhuav & Crystalizing kauj ruam

Thaum cov khoom tau txais mus rau qhov kub thiab txias, qhov ceev ntawm lub nruas yuav raug nce mus rau ntau dua rotating ceev kom tsis txhob muaj cov clumping ntawm cov khoom.Nyob rau tib lub sijhawm, lub zog hluav taws xob infrared yuav tau nce ntxiv kom tiav qhov ziab.Tom qab ntawd lub nruas rotating ceev yuav qeeb dua.Feem ntau cov txheej txheem ziab yuav tiav tom qab 15-20mins.(Lub sijhawm caij nyoog nyob ntawm qhov khoom ntawm cov khoom siv)

>> Tom qab ua tiav cov txheej txheem kom qhuav, IR Nruas yuav cia li tso cov khoom siv thiab rov ua lub nruas rau lub voj voog tom ntej.

Qhov tsis siv neeg refilling nrog rau tag nrho cov tsis muaj feem cuam tshuam rau qhov sib txawv kub ramps yog tag nrho kev koom ua ke nyob rau hauv lub xeev-of-the-art Touch Screen tswj.Thaum tsis pom qhov ntsuas kub thiab ntsuas kub rau cov khoom siv tshwj xeeb, cov kev teeb tsa no tuaj yeem khaws cia raws li cov zaub mov txawv hauv kev tswj hwm.

Peb Qhov Zoo

Nquag PET Lub raj mis flakes los yog daim ntawv seem nrog thawj theem noo noo txog li 10000-13000ppm.PET Lub raj mis flakes los yog daim ntawv seem (Virgin los yog tov) yuav recrystallized nyob rau hauv Infrared siv lead ua tshuab ziab khaub ncaws nyob rau hauv 20mins, lub ziab kub yuav yog 150-180 ℃ thiab qhuav rau 50-70ppm, ces pub rau ib leeg ntsia hlau extruding system rau ntxiv ua.

● Txwv tsis pub cov dej degradation ntawm cov viscosity.

● Tiv thaiv kom tsis txhob nce qib AA rau cov ntaub ntawv nrog cov khoom noj

● Ua kom muaj peev xwm ntawm cov kab ntau lawm mus txog 50%

● Kev txhim kho thiab ua kom cov khoom zoo ruaj khov-- Kev sib npaug thiab rov ua kom muaj dej noo ntawm cov khoom

● Txog li 60% tsawg zog siv dua li cov tshuab ziab khaub ncaws

● Tsis muaj kev sib cais ntawm cov khoom nrog ntau qhov sib txawv

● Independent kub thiab ziab lub sij hawm teem

● Yooj yim huv thiab hloov cov khoom siv

● Kev pib sai sai thiab kaw sai dua

● Uniform crystallization

● Tsis muaj pellets clumping & stick

● Ua tib zoo kho cov ntaub ntawv

Lub rooj sib piv

| Yam khoom | IRD Tshuab ziab khaub ncaws | Pa tshuab ziab khaub ncaws |

| Hloov nruab nrab | Tsis muaj | Cua kub |

| Thaum tshav kub kub hloov | Ob leeg sab hauv thiab sab nraud ua ke. | Los ntawm sab nraud mus rau sab hauv particle maj mam. |

| Zog | Txuag tsawg kawg 20 ~ 50% lub zog piv rau cov tshuab ziab khaub ncaws. | Siv zog ntau. |

| Lub sijhawm txheej txheem | 1. Crystallization & ziab: Lawv tau ua tiav ib txhij hauv li 8 ~ 15 feeb. 2. Qhuav thiab crystallization ntawm ib lub sij hawm | 1. Crystallization: Txog 30 ~ 60 feeb. 2. Qhuav: Txog 4 ~ 6 teev. |

| Cov dej noo | 1. Nyob rau hauv 50-70 PPM tom qab IRD ua tiav. | 1. Siv sijhawm 30 ~ 60 feeb los hloov amorphous PET rau crystallized PET ua ntej. 2. Nyob rau hauv 200PPM tom qab li 4 teev dehumidifier tiav. 3. Nyob rau hauv 50 PPM tom qab ntau tshaj 6 teev dehumidifier ua tiav. |

| Lub sijhawm ua haujlwm | 20 feeb | Ntau tshaj 6 teev. |

| Kev hloov khoom siv | 1. Yooj yim & nrawm dua. 2. Muaj tsuas yog 1 ~ 1.5 npaug ntawm lub peev xwm ntawm cov khoom siv ib teev nyob rau hauv lub buffer hopper. | 1. Nyuaj & maj mam. 2. Muaj 5 ~ 7 lub sij hawm muaj peev xwm ntawm cov khoom siv ib teev twg hauv crystallizer & hopper. |

| Kev ua haujlwm | Yooj yim --- Los ntawm Siemens PLC tswj

| Nws yog qhov nyuaj xws li nws yuav tsum muab me ntsis crystallized PET rau hauv crystallizer thaum pib ua haujlwm. |

| Kev tu | 1. Yooj yim. 2. Cov nqi kho mob qis dua. | 1. Nyuaj. 2. Cov nqi kho mob siab dua. |

Tshuab duab

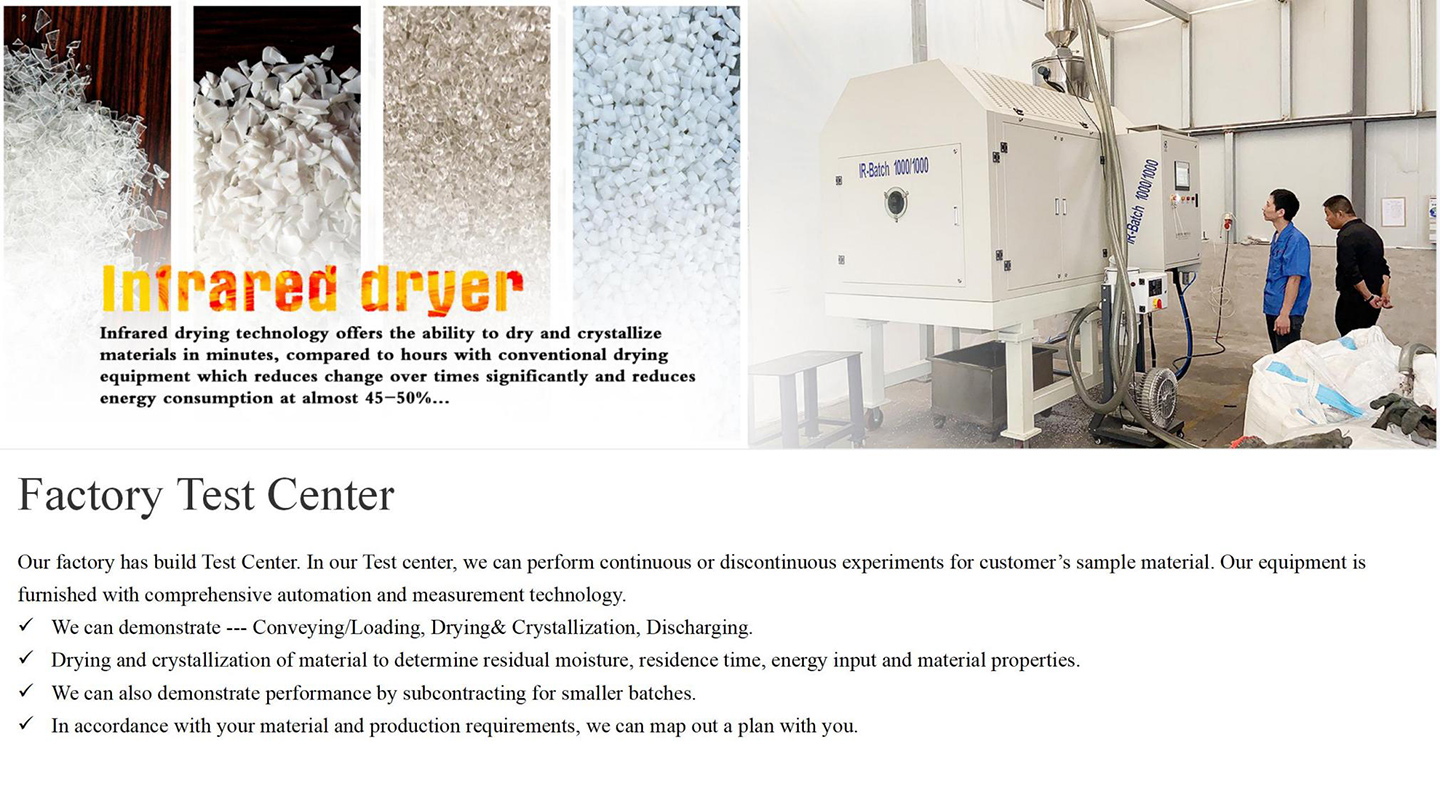

Khoom siv kuaj dawb

Cov kws tshaj lij engineers yuav ua qhov kev xeem.Koj cov neeg ua haujlwm raug caw tuaj koom nrog peb txoj kev sib koom ua ke.Yog li koj muaj ob qho tib si muaj peev xwm los pab txhawb thiab muaj lub sijhawm los pom peb cov khoom hauv kev ua haujlwm.

Tshuab Installation

>> Muab cov kws tshaj lij engineer rau koj lub Hoobkas los pab kev teeb tsa thiab cov khoom siv ua haujlwm

>> Txais aviation plug, tsis tas yuav txuas hluav taws xob xaim thaum cov neeg siv khoom tau txais lub tshuab hauv nws lub Hoobkas.Yuav kom yooj yim lub installation kauj ruam

>> Muab cov yeeb yaj kiab ua haujlwm rau kev teeb tsa thiab kev qhia ua haujlwm

> > Txhawb nqa online service