PLA PET thermoforming Sheet extrusion kab

Infrared Crystal tshuab ziab khaub ncaws + PET Sheet Extrusion kab

Qhov zoo peb ua

> > LANDA txhim khoIb leeg ntsia hlau extrusion kab nrog Infrared siv lead ua tshuab ziab khaub ncawsrau daim ntawv PET, 20mins ua ntej ziab thiab crystallization, qhov kawg ya raws tuaj yeem yog ≤50ppm ( Tshuab kab Ua haujlwm ruaj khov, daim ntawv kawg zoo ruaj khov)

Cov kab extrusion muaj cov khoom siv hluav taws xob tsawg, cov txheej txheem tsim khoom yooj yim thiab kev saib xyuas yooj yim.

Lub segmented ntsia hlau qauv tuaj yeem txo qhov viscosity poob ntawm PET resin, symmetrical thiab nyias-wall calender yob txhim kho cov nyhuv txias, lub peev xwm thiab daim ntawv zoo.

Ntau cov khoom siv dosing feeder tswj cov feem pua ntawm cov khoom tshiab, cov khoom siv rov ua dua tshiab thiab cov khoom siv tswv yim meej,.

Daim ntawv tau dav siv rau thermoforming ntim kev lag luam.

> >Infrared siv lead ua tshuab ziab khaub ncaws ----- Qhuav & Crystalize R-PET flakes / chips hauv 20mins ntawm 30ppm los ntawm kev txuag 45-50% tus nqi hluav taws xob.

※Limiting hydrolytic degradation ntawm viscosity.

※ Tiv thaiv kom nce qib AA rau cov khoom siv nrog kev sib cuag zaub mov

※ Ua kom muaj peev xwm ntawm cov kab ntau lawm mus txog 50%

※ Kev txhim kho thiab ua kom cov khoom zoo ruaj khov-- Kev sib npaug thiab rov ua kom cov dej ntws tawm ntawm cov khoom siv

Txo cov nqi tsim khoom ntawm daim ntawv PET: Txog li 60% tsawg zog siv dua li cov tshuab ziab khaub ncaws

Instant start-up thiab ceev ceev kaw --- Tsis xav tau ua ntej cua sov

Kev ziab & crystallization yuav ua tiav hauv ib kauj ruam

Txhawm rau txhim kho lub zog tensile ntawm daim ntawv PET, Ua kom tus nqi ntxiv--- Thaum kawg ya raws tuaj yeem yog ≤30ppm los ntawm 20minsQhuav & Crystalization

- Lub tshuab kab yog nruab nrog Siemens PLC system nrog ib qho tseem ceeb nco ua haujlwm

- Npog thaj tsam ntawm me me, qauv yooj yim thiab yooj yim rau kev khiav lag luam thiab txij nkawm

- Independent kub thiab ziab lub sij hawm teem

- Tsis muaj kev sib cais ntawm cov khoom nrog ntau qhov sib txawv

- Yooj yim ntxuav thiab hloov cov khoom siv

>> PET Extrusion tshuab kab

| Qauv | Ntau txheej | Ib txheej | Ua tau zoo heev |

| Extruder specification | LD75 & 36/40-1000 | LD75/40-1000 IB | LD95 & 62/44-1500 |

| Thickness ntawm cov khoom | 0.15-1.5 hli | 0.15-1.5 hli | 0.15-1.5 hli |

| Main lub cev muaj zog | 110kw / 45kw | 110 kwv | 250kw/55kw |

| Max extrusion muaj peev xwm | 500kg / h | 450kg / h | 800-1000kg / h |

Tshuab lis

| Tshuab Composition | ||

| NO | Tshuab | Ntau |

| 1 | PET Infrared Crystal tshuab ziab khaub ncaws | 1set ib |

| 2 | Nqus ntsia hlau feeder | 1set ib |

| 3 | Ob chav ntsia hlau extruder | 1set ib |

| 4 | Lub tshuab nqus tsev tsis zoo siab | 1set ib |

| 5 | Ob chav channel lim | 1set ib |

| 6 | Melt metering twj tso kua mis | 1set ib |

| 7 | PET tshwj xeeb pwm tuag | 1set ib |

| 8 | Peb-yob calendering tsim ib feem | 1set ib |

| 9 | Silicone roj txheej thiab Cub ntaus ntawv | 1set ib |

| 10 | Ntug cov khoom siv txiav | 1set ib |

| 11 | Ntug cov ntaub ntawv rov qab ntaus ntawv | 1set ib |

| 12 | Ob chav chaw nres tsheb winding system | 1set ib |

| 13 | SIEMENS human-machine interface tswj qhov system | 1set ib |

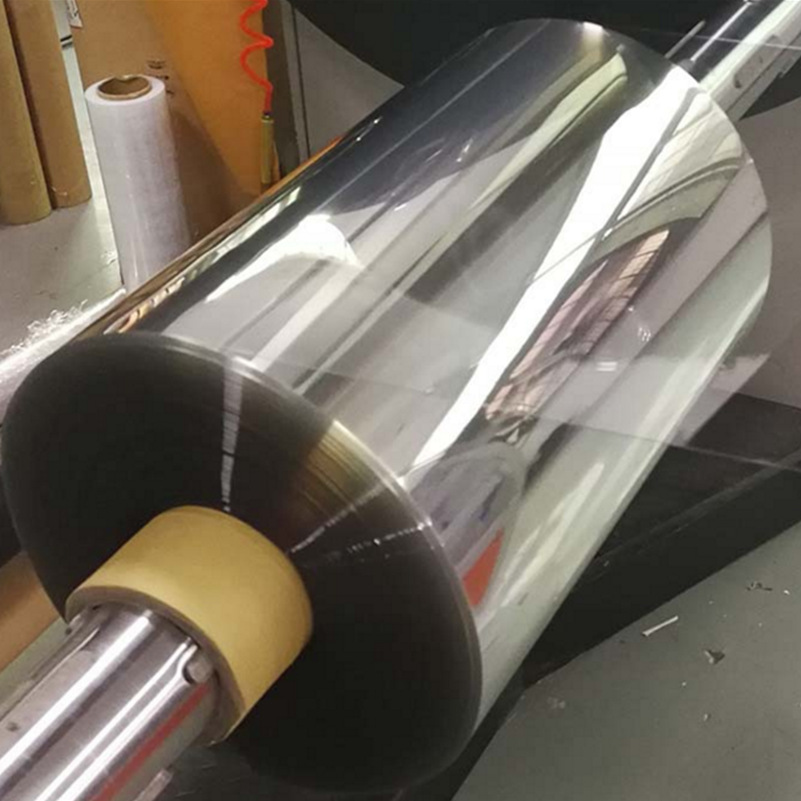

Tshuab duab

FAQ

Q: Dab tsi yog qhov kawg ya raws koj tuaj yeem tau txais? Koj puas muaj kev txwv rau thawj zaug ya raws ntawm cov khoom siv raw?

A: Qhov kawg ya raws peb tuaj yeem tau txais ≤30ppm (Siv PET ua piv txwv). Thaum pib ya raws tuaj yeem yog 6000-15000ppm.

Q: Peb siv ob npaug ntawm cov ntsia hlau extruding nrog lub tshuab nqus tsev degassing rau PET Sheet extrusion, peb puas tseem yuav tau siv lub tshuab ziab khaub ncaws ua ntej?

A: Peb xav kom siv Pre-dryer ua ntej extrusion. Feem ntau xws li cov txheej txheem muaj qhov yuav tsum tau nruj me ntsis ntawm thawj zaug noo noo ntawm cov khoom siv PET. Raws li peb paub PET yog cov khoom siv uas tuaj yeem nqus cov dej noo los ntawm huab cua uas yuav ua rau cov kab extrusion ua haujlwm tsis zoo. Yog li peb xav kom siv lub tshuab ziab khaub ncaws ua ntej koj lub tshuab extrusion:

> > Limiting hydrolytic degradation ntawm viscosity

> >Tiv thaiv kom nce qib AA rau cov khoom siv nrog kev sib cuag zaub mov

> > Ua kom muaj peev xwm ntawm cov kab ntau lawm mus txog 50%

>> Kev txhim kho thiab ua kom cov khoom lag luam zoo ruaj khov - Sib npaug thiab rov ua kom cov dej ntws tawm ntawm cov khoom

Q: Peb yuav siv cov khoom tshiab tab sis peb tsis muaj kev paub txog kev ziab cov khoom no. Koj puas tuaj yeem pab peb?

A: Peb lub Hoobkas muaj Chaw Xeem. Hauv peb qhov chaw kuaj mob, peb tuaj yeem ua qhov kev sim tsis tu ncua lossis tsis tu ncua rau cov neeg siv khoom tus qauv. Peb cov cuab yeej tau muab kho nrog kev ua tiav automation thiab ntsuas tshuab.

Peb tuaj yeem ua qauv qhia --- Kev xa khoom / thauj khoom, ziab & crystallization, tso tawm.

Kev ziab thiab crystallization ntawm cov khoom los txiav txim qhov seem ntawm cov dej noo, lub sijhawm nyob, lub zog nkag thiab cov khoom siv.

Peb kuj tuaj yeem ua kom pom kev ua tau zoo los ntawm kev sib cog lus rau cov khoom me me.

Raws li koj cov khoom thiab cov kev xav tau ntau lawm, peb tuaj yeem ua daim ntawv qhia nrog koj.

Cov kws tshaj lij engineers yuav ua qhov kev xeem. Koj cov neeg ua haujlwm raug caw tuaj koom nrog peb txoj kev sib koom ua ke. Yog li koj muaj ob qho tib si muaj peev xwm los pab txhawb thiab muaj lub sijhawm los pom peb cov khoom hauv kev ua haujlwm.

Q: Lub sijhawm xa khoom ntawm koj IRD yog dab tsi?

A: 40 hnub ua haujlwm txij li peb tau txais koj cov nyiaj tso rau hauv peb lub tuam txhab account.

Q: Yuav ua li cas txog kev teeb tsa ntawm koj IRD?

Cov kws tshaj lij engineers tuaj yeem pab txhim kho IRD system rau koj hauv koj lub Hoobkas. Los yog peb tuaj yeem muab cov kev pabcuam qhia hauv kab. Tag nrho lub tshuab txais aviation plug, yooj yim rau kev sib txuas.

Q: Dab tsi yog IRD tuaj yeem thov rau?

A: Nws tuaj yeem ua rau lub tshuab ziab khaub ncaws ua ntej

PET / PLA / TPE Sheet extrusion tshuab kab

PET Bale pluaj ua tshuab kab

PET masterbatch crystallization thiab ziab

PETG Sheet extrusion kab

PET monofilament tshuab, PET monofilament extrusion kab, PET monofilament rau broom

PLA / PET zaj duab xis ua tshuab

PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Lub raj mis, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA, PBAT, PPS thiab lwm yam.

Thermal txheej txheem rau covtshem tawm cov so oligomeren thiab volatile Cheebtsam.